- Tips

- technology

- Frequently Asked Questions

- Tests

- mAh capacity

- Rated Capacity

- comparison

- everActive

- Batteries vs rechargeable batteries

- Durability of rechargeable batteries

- Efficiency of rechargeable batteries

- battery voltage

- Accumulated energy

- LR03 AAA

- LR6 AA

- eneloop

- AG13 LR1154 LR44

- CR 2032

- Delta V

- Charge Cycles

- internal resistance

- charge level

- memory effect

- accredited test

- SR44 357

- Hearing Batteries 675

- SR626 377

- Watch Batteries

- Polarity

- Mah

- passivation

- LS 14250

- LS 14500

Are my rechargeable batteries already used up? How to assess the condition, condition and age of your rechargeable batteries?

The problem is complex, and the answer is of interest to both users and sellers who face complaints from their customers. We will try to help everyone interested in this topic.

1. Assessing the age of the battery

Every major manufacturer MUST put the date of manufacture on their batteries – it can be encrypted (in the code), but a reliable seller/manufacturer should be able to determine when the battery was manufactured.

Why is the age of the battery so important?

A cell that is 2 years old (and more) will usually be more unreliable than brand new cells – even if it has not been regularly used or heavily used.

It is worth knowing that international manufacturer standards, used to assess the quality of Ni-MH batteries, no longer even specify the criteria that a cell must meet after 2 years from the date of production – such a cell can still be quite useful, but in the case of the most strenuous cells, with high capacities, degradation is noticeable after such a period.

2. Measurement of the usable capacity of the battery (from discharge)

There are plenty of chargers on the market that, according to the manufacturers' assurances, can measure the capacity of rechargeable batteries. Unfortunately, there are far fewer chargers that do it reliably or precisely enough.

If we have the right everActive, Xtar or Eneloop charger, it is a relatively easy element to verify.

The capacity result obtained on a given battery must again be related to its age or possibly the time that has passed since its purchase. If the battery is new, fresh from purchase, it should show a capacity close to its nominal capacity, if after a few cycles/discharges its capacity is still more than 5% lower than what the manufacturer declares – it is worth taking a closer look at it.

[Remember that to assess the capacity of the battery, we must perform a full battery charge and discharge cycle. The value obtained after a full discharge indicates the actual capacity of the battery.]

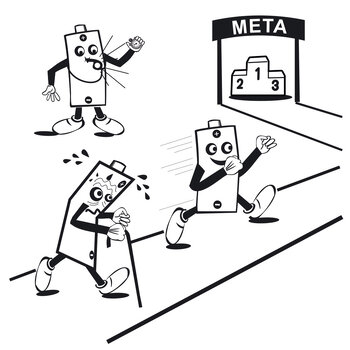

A rechargeable battery does not have to and usually is not able to maintain its full usable capacity for many years. The same is true when our battery is longer in use.

The usability criterion for Ni-MH cells is 60% of the nominal capacity, and for Li-ion cells 80%. A permanent decrease in capacity only below these values may be a reason to complain about the cells during their warranty period (2 years by default).

3. Measurement of the internal resistance of the battery

In the case of Ni-MH cells, this is an element that will cause us to notice a decrease in the efficiency of rechargeable batteries even faster. An increase in resistance above 200-300 milliohms already means significant degradation of the cells and such values in typical applications should not appear during the first months or even a year of operation.Resistance measurement, as well as capacitance measurement, can be done in an appropriate charger – e.g. everActive NC-3000 (for Ni-MH cells) or UC-4200 (both Ni-MH and Li-ion).

If we do not have a suitable charger, we should get a voltmeter (multimeter) and some simple load, preferably drawing about 300-1000 mA from our battery (an ordinary 4.7 Ohm / 5W resistor will work well for both Ni-MH 1.2V and Li-ion 3.7V cells).

For the measurement, we need a battery that is at least 50% charged.

We measure the voltage on such a battery, without a load (resistor) connected, then connect our resistor between the +/- poles and record after about 1-2 seconds another voltage indication directly on the battery.

The second indication will be lower – the value of the voltage drop will be higher the higher the resistance of our battery – if in such conditions we record a drop higher than 0.1 V on a Ni-MH cell, and above 0.3 V on a Li-ion cell, it is worth complaining about such a cell.

4. Cell voltage measurement (?)

Unfortunately, measuring the voltage alone will not do us anything – especially in the case of Ni-MH cells – we will not even correctly assess the degree of charge of such a battery by the voltage alone – we wrote about it in another post.

5. Checking the battery on the battery tester (?)

Usually, such a test is also useless – even on heavily used batteries, simple tilting and digital testers show quite optimistic values. In addition, before such a test, we must be sure that the battery has been properly charged.

Summary

In our practice, it usually turns out that the claimed cells easily meet the 2/3 criteria – they achieve the correct capacitances, have low resistance, and yet do not work at the customer's site. The most common reason is: improper charging of the batteries (low quality of the charger used), lack of attempts to repeat the charging process in the case of heavily dependent cells, as well as such a trivial reason as the lack of proper contact between the battery and the contacts/springs in the basket of the device. Less often, the problem lies in a device that does not tolerate work with any rechargeable batteries – although such devices still happen.

Copying the content of the article or its part without the consent of a representative of Baltrade sp. z o.o. is prohibited.